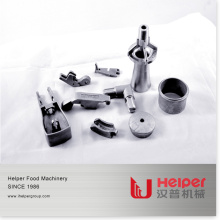

Introducing the "Moldy Magic" Silicate Mold Shell Investment Casting Parts!

Calling all professionals who want to cast their worries away and embrace the hilarious side of industrial processes. Our Moldy Magic parts will have you in stitches as you witness the transformation of mundane molds into extraordinary works of art. Picture this: your colleagues' jaws dropping as they witness your impeccable casting skills, all thanks to our Silicate Mold Shell. But wait, there's more! Our parts are so versatile, they can even double as conversation starters at awkward office parties. So why settle for boring when you can have a mold-tastic time with Moldy Magic? Get ready to cast and laugh your way to success!

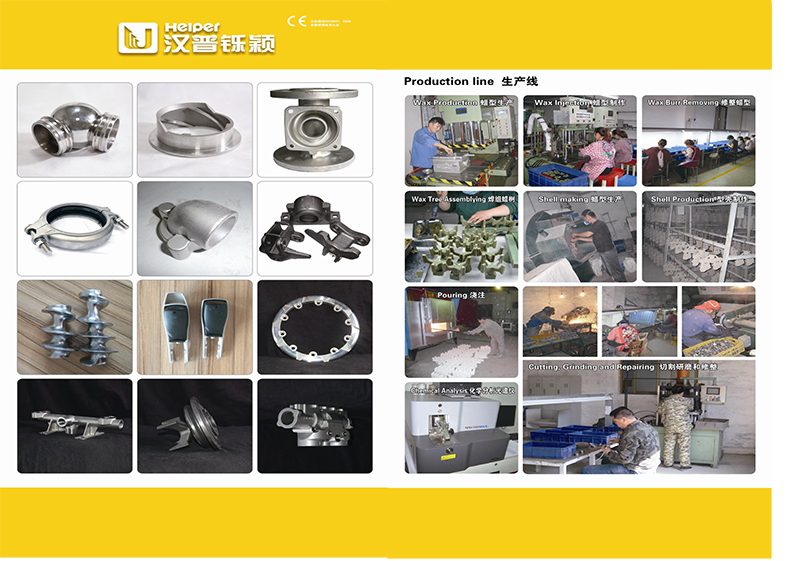

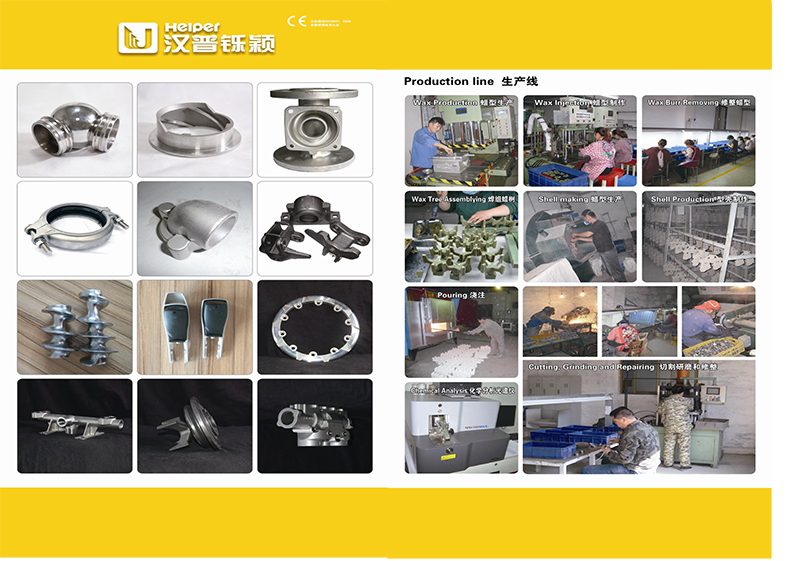

Production flow of Precision Casting Parts is introduced as following, so let us know your specific requirements, and we will assist you to make perfect products with good prices.

Drawing & Samples → Mould making → Die casting → Deburring→ Drilling and threading → CNC Machining → Polishing → Surface treatment → Assesmbly → Quality inspection → Packing → Shipping

Material:

Carbon steel low, alloy steel stainless, steel steel, 304 (CF8), 316 (CF8M), 304L, 316L, and others.

Standard:

ASTM, AISI, DIN, NF, JIS, AS BS, etc

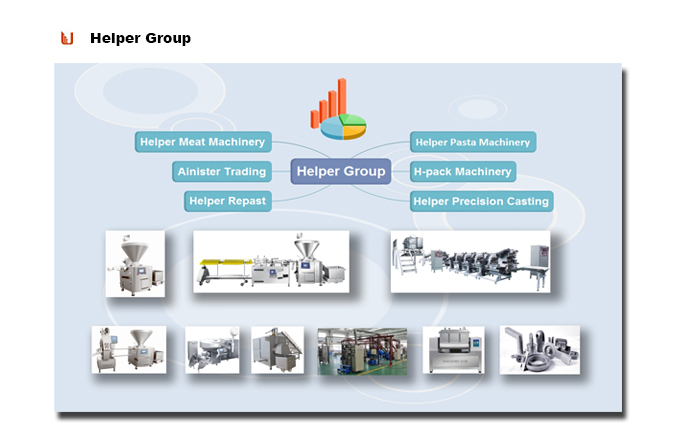

Application:

Automobile, ships, machinery agriculture, machinery components mechanical, equipment electrical, machinery engineering, machinery mining, machinery petroleum, etc.

Technology:

Silicon sol Investment Casting, lost wax casting

Treatment: Surface

Blasting, polishing, painting, Treatment Hot, galvanized

Surface Roughness: Finish/Ra 6.4~12.5

Weight: Casting Kg 0.02~130

Product Categories : Investment Casting

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now

Contact Now

Contact Now